It’s Coil Replacement Season

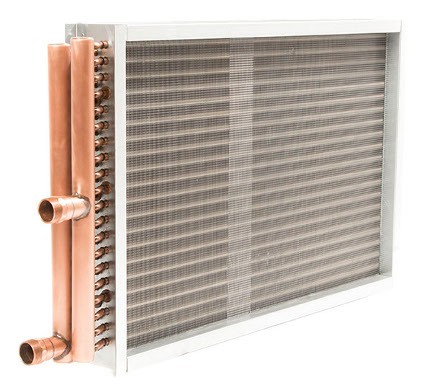

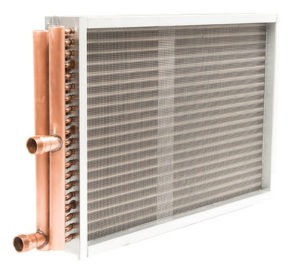

The “holiday season” may be over, but the “coil replacement season” is in full swing in many areas of the country. Particular attention must be paid to the condition of your heating and cooling coils. Heating coils that aren’t providing the needed BTUH capacity can become a huge problem in the dead of winter, while cooling coils and condenser coils must be ordered and replaced now in order to have adequate cooling during the hot summer months.

Why Do Heating Coils Need Replacing?

Heating coils are normally 1 or 2 row designs. Rarely are they replaced because of air side loading (which increases the air resistance), because there’s not enough dense surface in a heating coil. Heating coils can have a freeze event (or multiple ones) that cause much of the primary surface to be disconnected from the fluid supply, drastically reducing the overall BTUH output of the coil. We’ve seen heating coils with 10 or more freeze holes that were repaired, and the tube(s) were simply disconnected from the water circuit. Any time you disconnect one tube, two or more tubes in the circuit are also disconnected from the fluid flow exacerbating the reduction in capacity.

Steam heating coils can freeze when the steam specialty hardware outside the coil doesn’t remove the condensate from the coil as rapidly as it’s formed. Many steam heating coils that handle below freezing air (preheat coils) do not have these components in the proper positions and/or are not sized properly. Theoretically, this means that the inside of the coil can’t be a negative pressure but may be only zero pressure. Traps need positive pressure to remove condensate freely. That’s the reason why a trap should be located 12” to 18” below the coil outlet. Each foot of leg is ½ lb. of positive pressure. The trap needs to be sized to 2 to 3 times the condensate lbs./hr. Many coils are mounted in air handlers that are floor mounted. The condensate coil connection is just a few inches from the floor, and you can create problems when you don’t have the 12” to 18” leg required to assure condensate removal.

All fluid coils that are either water or steam treated are prone to corrosion problems over time. There are many byproducts from this process that increase year after year until the volume is such that it attacks copper. Corrosive holes in copper can be ratty and pinhole types – usually on the bottom half of the tube (3 o’clock and 9 o’clock). You can have a decade of leak free coils and suddenly have multiple leaks in the following few years. Remember: Test results from treatment reports do not include looking for specific contaminants. That’s why owners are surprised by this sudden change in their coil systems.

Why Do Cooling Coils and Condensers Need to be Replaced?

It’s obvious that most of the reasons for replacing heating coils include fluid cooling coils. Many cooling coils need to be drained during their dormant season or filled with glycol (antifreeze). When they are drained, unfortunately, there are many coil designs (circuitry) that have tubes below the drain connection located on the coil’s manifold. There can be from 2 to 10 tubes that will still have residual water in them. Meanwhile, the maintenance personnel think they have drained it totally. You need to understand this dynamic and pull a vacuum to alleviate this problem.

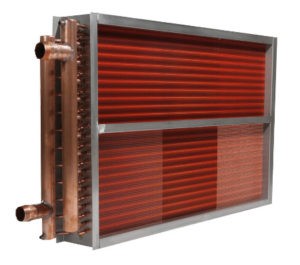

Cooling coils are very dense since most are at least 4 rows of tubing in the direction of the air flow, and many can be as much as 10 rows in the direction of the air flow. There has also been a propensity to ignore the density further by selecting a greater number of fins per inch. Based on the lack of filtration above and a nonexistent coil cleaning schedule, coils can load to a point where they need replacement. You can clean a coil from each side and maybe 2 rows on each side. If the dirt or foreign material migrates into the inner core of a coil with 6 or more rows in the direction of the airflow, the coil may need replacing.

Condenser coils have 2 major reasons for being replaced. 1) They can become dirt laden surfaces that reduce the condenser air flow to the point that it causes high refrigerant pressures that over time cause compressor failures. Remember: Coil cleaning of a condenser is imperative since condensers are the only coils mounted in HVAC installations without a filter on its entering air side. 2) They need to be replaced when vibration holes are at or near the tube sheet of the coil. These holes are caused by increased vibration from compressors or condenser fans and motors. Some unit designs do not have adequate structural integrity in or near condenser coil sets and vibrating equipment radiates adverse vibration into the coils.

USA Coil & Air has been the leader in replacement technology for 4+ decades. We have the knowledge and experience to diagnose and explain the need for a coil replacement. We don’t want to replace a problem knowing it will reoccur over time. We’ve built thousands of coils, and sometimes we only need the make and model number of the units and/or coils.