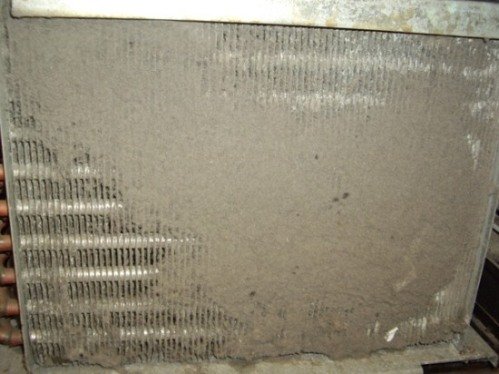

In a perfect world, most cooling coils should operate efficiently for twenty years or more. Lack of proper maintenance, inappropriate applications, corrosion, and less-than-stellar modern-day construction all affect the life expectancy of cooling coils. There are three major reasons for premature cooling coil replacement as follows: Increased air resistance due to the plugging of the coil surface. What causes this plugging? There is an increase...

Read More