How Does an Evaporator Coil Work?

Evaporator coils are a mystery to many technicians and engineers in the HVAC industry. Evaporator coils don’t have any movable parts, and a coil can have many different capacities based on what it’s fed from the refrigerant side of the closed refrigeration loop.

If a self-contained unit is used to provide air conditioning in a space, the evaporator coil will have been engineered to match the other components in the package (compressors, condenser, valves etc.). The unit may be tagged as a “10-ton unit”, and the components will all be sized for 10 tons. The unit may have a quantity of two circuits at 5 tons each, and the evaporator coil will have two circuits as well.

Most units that are a standard tonnage are selected at typical conditions for most of the country. That would be 400 CFM per ton (4,000 CFM if a 10- ton unit), 80/67 entering air (dry bulb and wet bulb standard return air conditions for an AC system), R-410A (most are now this refrigerant type), and approximately 44 to 45 degrees F suction temperature. At these conditions and 400 CFM per ton, the leaving conditions would normally be in the high 50’s discharge temperature.

An evaporator coil receives the refrigerant through an expansion valve and into a distributor barrel. The barrel is sized to fit the number of distributor leads into the refrigerant exit side, and the expansion valve meters the amount of refrigerant that is allowed into the distributor. There is an opening inside the distributor barrel with a hole in it sized to allow the tonnage into the distributor leads that follow. This opening is always sized for the maximum amount of refrigerant. If it’s a 10-ton AC system, a 10-ton orifice is used. If the coil has two 5-ton circuits, then the opening is 5 tons in each circuit.

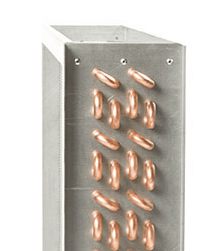

As stated, the distributor has small diameter tubes (known as distributor tubes) brazed to the exit side of the distributor. The number of distributor feeds is engineered to create an equal amount of refrigerant to each distributor lead. This is more complicated than meets the eye. You will notice that these distributor leads are the same length. This is mandatory if you want each distributor lead to release the same amount of refrigerant into the coil tubes. Since the bottom tubes and top tubes are further away from the centered distributor, the distributor tube bundle is crimped.

Remember: All the tubes must be the same length, and the centered tubes should be closer to the back of the distributor then the ones at the top and bottom.

The proper amount of refrigerant has now been “distributed” into the coil tubes at a pressure drop that is optimum for a typical AC compressor(s). The refrigerant begins to absorb the heat from the air that’s being distributed by a nearby fan across the finned surface of the coil, and the amount of heat removed from the air is received into the refrigerant. The refrigerant now leaves the evaporator coil and goes to the compressor where the total heat is removed by a condenser.

Remember: There is the heat that the refrigerant received at the evaporator coil and the heat of compression. The condenser must remove both, and this is generally called “total heat of rejection”.

Problems with evaporator coils

- Undersized selection – In a split system, under sizing is normally done on purpose, because there may not be enough room for the coil or they are trying to meet an intermediate tonnage with an over-sized condenser-compressor and undersized evaporator.

- Over-sized selection – If an evaporator is drastically over-sized, this can be even worse than under sizing. Suction temperature can fall and cause frost when temperatures fall below 32 Degrees F.

- Inadequate air flow – This can happen when a fan isn’t able to distribute the needed air through a coil. It may be due to an undersized fan and drive package or the finned tube surface is so dirty that the coil resistance can be as high as twice the clean resistance.

- Improper distributor/expansion valve hardware – Many times we’ve noticed that manufacturers place whatever is in stock into a system, and it may not be the most optimum hardware. This can cause temperature fluctuations, valve hunting, and higher running AC pressures.

USA Coil & Air prides itself on its ability to identify evaporator coil problems. Many times, coils wear out with multiple leaks in joints or become dirt laden over time. However, there are systems that require a specialist to analyze the system problem and recalculate/redesign an evaporator coil that will work in any system. Try USA Coil for your evaporator coil problems and replacements, we solve problems without creating new ones.