Fan Coil Unit Performance Issues

Many existing fan coil unit installations have inherent performance issues that relate to the original design and/or systemic conditions that decrease overall performance. Fan coil units are direct drive – the motor is directly connected to a squirrel cage fan. This arrangement clearly defines the volume of air based on external static pressure and the amount of dehumidifying at the chilled water coil. There’s very little room for miscalculation with these types of units. The following are the top reasons why a fan coil unit isn’t cooling a space:

Original design reasons:

- The amount of external static pressure (resistance measured outside the unit) has drastically reduced the overall cfm air volume. A fan coil unit’s basic capacity will always be about 400 cfm/ton. Example: A 1½ ton unit will be close to 600 cfm and might be at .1” external static pressure. If you include an inlet and/or outlet duct and grilles, etc., it may add up to .25” external resistance, and the 600 cfm could be reduced to 450 cfm.

- The standard coil does not dehumidify enough for comfort within the space. Many fan coil units have 3-row chilled water coils that will obtain the dry bulb temperature, but the removal of water leaves the relative humidity too high. We like to see 4-row chilled water coils instead of 3 rows.

- Many or all the units were designed for a specific chilled water temperature; i.e., 45 degrees F, but the actual temperature is 2 to 3 degrees warmer. Example: 48 degrees F entering water temperature yields a 4-degree higher leaving air temperature, which will create problems cooling down the space during peak load.

- Many or all the units were designed for a specific GPM volume. Example 3.6 GPM for a 1½ ton unit – 10 degrees water temperature difference that’s required to meet the BTUH unit tonnage. Due to pump capacity problems, the units can be starved for water flow and may reduce capacity by up to 20%.

- Unit location and air flow isn’t enough to adequately cool the entire space. Remember that fan coil units have return air locations near the supply outlet location and somewhere on the unit. Many times, there are areas in the room that will never have air flow and will be considered hot spots.

- Thermostat locations that are too close to the supply and/or the return air streams that cycle the thermostat off too quickly. Thermostat locations must be placed in a position that reads the room temperature and not the air stream temperature.

Systematic and maintenance reasons:

- Cleaning of filters is very important because any extra pressure will reduce air flow. Most system designs have marginal air flow to begin with, so keeping filters clean is imperative.

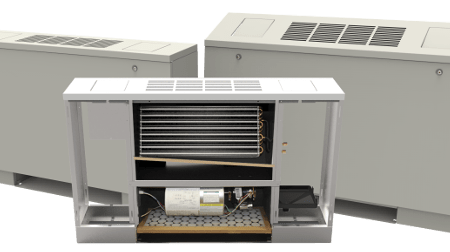

- Cleaning of chilled water coils is also very important. Most fan coil unit designs have the fans blowing the air through the coils located downstream. These coils can be 3 or 4 rows and can be as high as 12 to 14 fins per inch. A mandatory cleaning schedule must be adhered to, so these coils don’t build up extra pressure and reduce air flow capacity.

- Closing of supply grilles will reduce overall air flow and BTUH capacity of a unit. Some units may have short ductwork runs to 2 spaces. Example: A hallway and a 2nd bedroom in a condo. Closing the bedroom supply grille will drastically increase the external static pressure and will cause the total air flow to be reduced.

- Faulty valves and controls that either cycle the unit on and off or do not allow the proper water flow into the unit will alter unit capacity. This equipment must be monitored and kept in good shape for proper unit operation.

USA Coil & Air has been a pioneer in the replacement fan coil unit market for 4 decades. When we are involved in unitary replacement, we want to have an active conversation about the issues shown in this article. As you can see, many of these issues occur at the time of design and original installation. We can provide quality alternatives to overcome some of these problems.

Examples: We build many arrangements and sizes that will fit the tight spaces where existing fan coil units are mounted, and we supply energy efficient motors and alternative speeds to allow for extra capacity and almost every type of valve and control imaginable. We also have a patented coil system with valving and piping that can overcome very high humidity areas that have occupancy problems during peak loads.