Direct Drive Fan Coil Units

Direct Drive Fan Coil Units

From design/build to large project retrofit, USA Coil & Air has almost every type and size covered when it comes to direct drive fan coil units. As one of the few remaining manufacturers of these smaller, high demand units, we not only provide you with the broadest range of design options to suit your installation or exactly match a replacement, but we have your unit when you need it. Vertical and horizontal fan coils, ceiling, wall, and a room mounted units can be designed for just about any need or requirement. Special control systems and valve packages included.

| UNIT TYPES |

|---|

| Two or four-pipe, Hydronic cooling/heating, Steam, Direct-Expansion (DX) and/or Electric Heat |

| Galvanized steel for hidden units & painted cabinets for exposed units |

| Direct Drive Horizontal 200 to 2000 CFM |

| Direct Drive Vertical 150 to 2200 CFM |

| OPTIONS |

|---|

| Different row combinations |

| ECM motors |

| Slope top & low boy designs |

| Large capacity unit design |

| Valve packages of all types |

| Thermostats and controls |

| Outside air for vertical models |

| Optional grilles |

| APPLICATIONS | |

|---|---|

| Hotels & Motels | Military bases |

| Condos, Apartments & Townhouses | Government Facilities |

| Hospital & Medical Facilities | Schools & Universities |

| Nursing Homes | Shopping Centers |

| Office Buildings | Pharmaceutical & Technology |

Shipping Option

Cost

7-12 Weeks (Varies during year)

Standard Shipment

2 Weeks & 4 Weeks Expedited

Call for pricing

See our Shipping Schedule for all other HVAC equipment offered.

Questions? Need more information?

Please call us at 800-USA-COIL!

Or send us a message using the form to the left.

Descriptive Information

BASIC UNIT

The basic unit and cabinet is fabricated of galvanized steel. Many units have decorative cabinets fabricated of heavy gauge steel, bonderized and finished with an attractive, oven-baked paint. The condensate drain pan is fabricated of galvanized steel with closed cell, fire retardant, foam insulation coating. Water never touches the metal pain; thus, the possibility of corrosion is minimized. Removable pan extensions are available at the coil header end of the horizontal unit to provide positive control of condensate from valves and controls. This extension, being easily removable, provides ready access to valves and piping after unit installation. Vertical units have a removable front panel lined with 1/2” woven glass fiber for thermal insulation and acoustic treatment. Removal of the front access panel provides access for easy servicing.

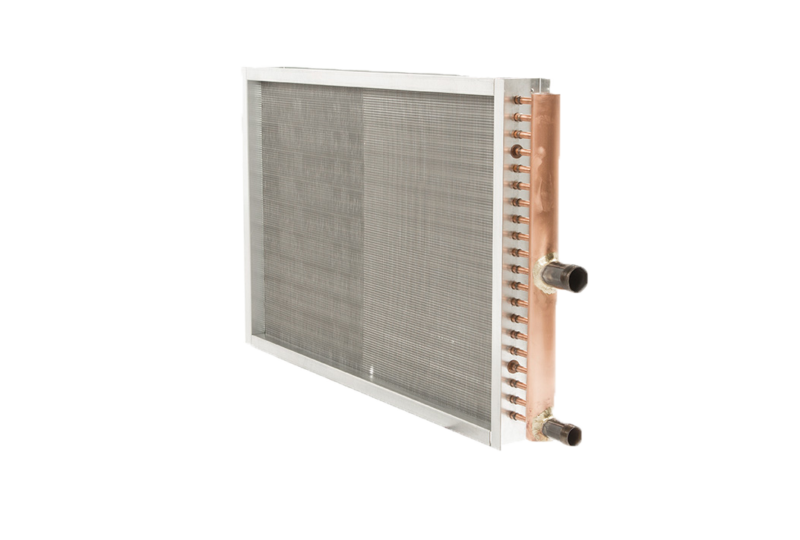

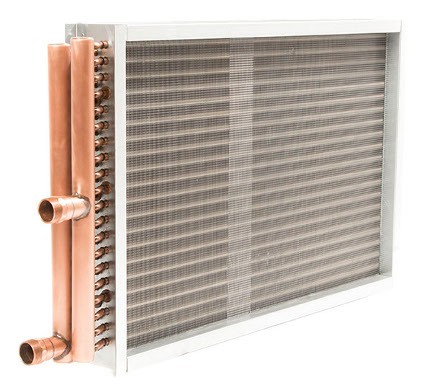

COILS

Coils have 1/2” O.D. copper tubes with aluminum fins mechanically bonded to the tubes. All coils are leak tested under water and are suitable for design working pressures of 250 psig @ 200° F. A variety of coil selections are available. The standard coil provides adequate capacity for most installations with an 8 to 10° design water temperature rise. A high capacity coil is offered for those installations requiring higher latent heat capabilities or those designed for a 12° water temperature rise. Also offered is a fourpipe coil consisting of standard or high capacity cooling with one and two rows of heating surface.

FILTERS

Standard filters are 1” throwaway glass fiber. Optional cleanable filters are available.

FANS

The fans are centrifugal, forward-curving, double-width wheels. Blower housings are galvanized steel with special rolled perimeter seams to provide added rigidity.

MOTORS

All motors are resilient-mounted, three-speed, with UNDERWRITERS listed thermal overload protection. Motor bearings are of the sleeve type of ball bearing type with oversized oil reservoirs provided to assure positive lubrication with minimum servicing required. Positive speed reduction is assured through careful matching of motor torque to blower loading. Standard motors are permanent split capacitor.

CERTIFICATION

All horizontal and vertical series units are certified in compliance with AHRI. All units are also listed by UNDERWRITERS’ LABORATORIES, INC. This listing signifies that USA Coil & Air’s fan coil units have been examined by UL and found to be in complete compliance with applicable standards.

Products and specifications subject to change without notice.

Latest From The Blog

View our latest blog news

-

What is Heat Transfer?

There are many terms used in the HVAC Industry. One that is often misunderstood is heat transfer. Wikipedia’s definition states that......

-

Invaluable Freeze Event Protection

USA Coil & Air has been marketing our patented, freeze-damage water and steam coil line for over 25 years under the......

-

It’s Coil Replacement Season

The “holiday season” may be over, but the “coil replacement season” is in full swing in many areas of the country.......