Alternative to Replacing Long Coils

Many heating and cooling coils are installed in air handling units with very limited access to the unit. This often occurs because the original designer didn’t give much thought to possible future replacement of the coils and fans. We have all seen ductwork, electric lines, water lines, boilers, chillers, pumps and other air handlers where it’s impossible to install a new coil. The pull length (or even height) is not available. It’s not difficult to cut up the old coil(s). The big question is, “How are you going to get a new coil(s) in the track?”

We have two main methods – 1) is a special, revolutionary “sectional coil design”, and 2) is a “two half coil design”.

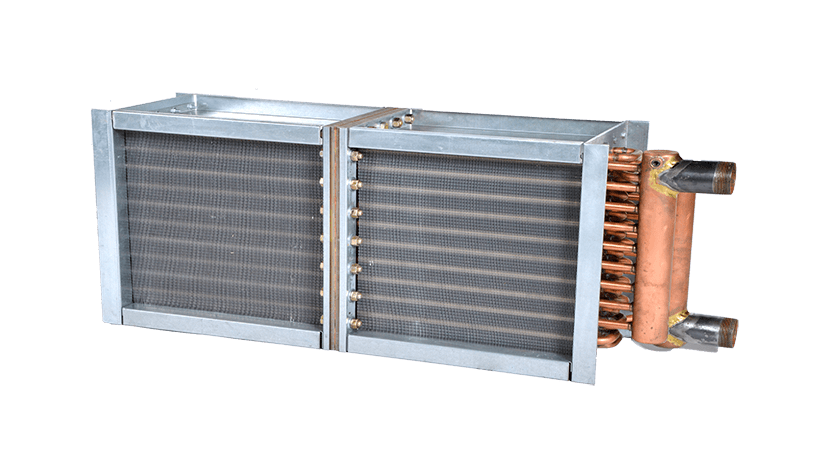

Sectional Coil Design

This design incorporates a front header end and a back-return bend end that are sealed together in the middle of the length of coil. Essentially, this gives you two sections that are about half the length of the original coil. There are matching tube sheets at one end of both pieces, as well as gaskets, that allow for a fluid tight connection where the two sections meet.

Two Half Coil Design

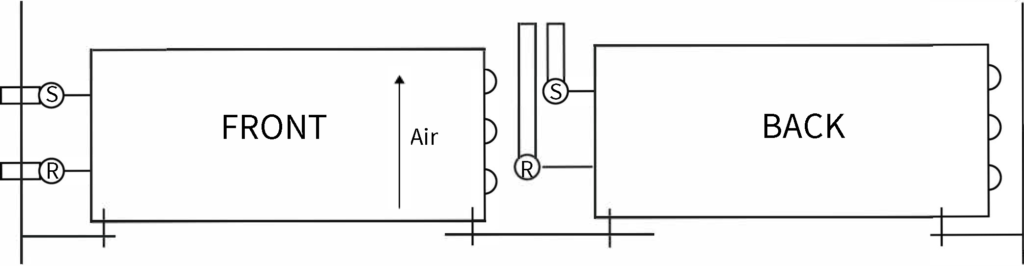

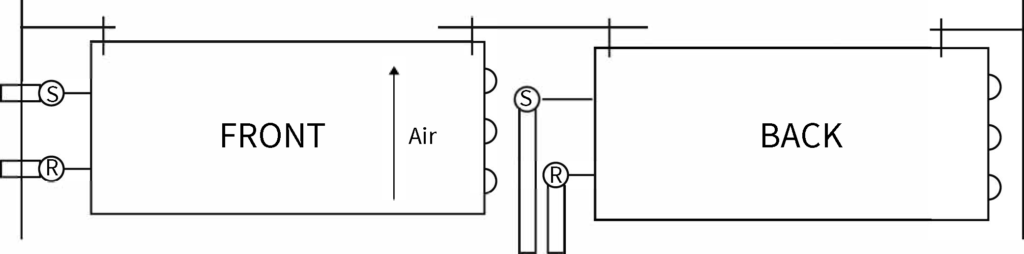

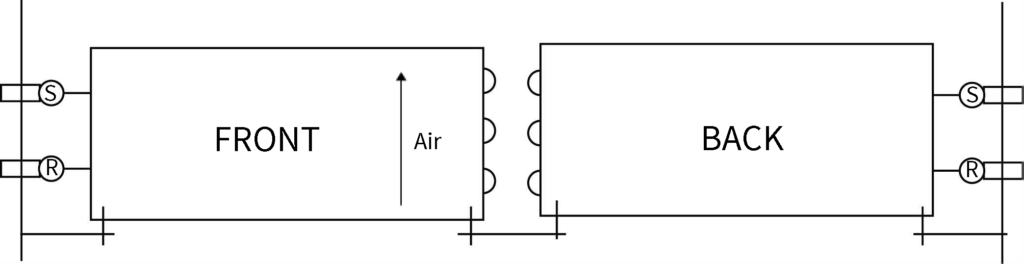

This design uses two individual coils to make up the length of the coil that has been removed. There are three sub-arrangements with this design. The installer can utilize the existing inlet and outlet piping at one end of the unit, just as they would if there was only one coil across the air stream. This coil can be provided with the same connection sizes and locations as the previously pulled coil. We will call this coil the “front side coil “- See Figure #1.

The three variations come into play with what we call the “backside coil”. The backside coil will need to be individually piped. This can be accomplished via three different arrangements.

- Figure # 1 above shows 90 degree turned connections in the direction of air flow.

- Figure # 2 above shows 90 degree turned connections into the air stream (air in the face).

- Figure #3 above shows the two coils butted back to back and piping to the backside coil on the other side of the unit.

How to determine which of these arrangements to use:

There are positive and negatives to these arrangements, and every one of them is based on cost and coil system performance.

For performance efficiency, the “sectional coil” design is preferable over the other alternatives, but the price is usually 50% to 70% higher than a 2 half coil option. The increased cost is based on heavier wall tube and extra heavy tube sheets, mating flanges, bolts, gaskets and tube end process. With this alternative, the coil face area will be the same, and performance can be matched exactly and have the same fluid side and air side pressure drops as well. The same supply and return connections can be utilized (not having an extra set of connections) and simple baffling. This arrangement may be required on dehumidifying coils (cooling coils), because all the other “two half coil arrangements” will reduce overall face area and may produce air velocities that cause “water carryover”. This can be determined using the original design data or actual CFM readings across existing coils.

The “two half coil” designs have a pricing advantage with prices approximately 50% – 70% less than the “sectional coil” design and approximately only 20-30% higher than a single coil replacement. However, you have to add back in the costs for mounting two coils instead of one and the extra piping and baffling required by two individual coils. There is also another problem that must be overcome – two coils have extra headers and return bends and subtract from the overall face area that existed. Many times, we can change the circuitry and/or fins per inch to overcome the reduced face area.

USA Coil has all your options covered for this special requirement. We have installed thousands of these coils over many decades, and throughout the country they are working correctly and efficiently in HVAC systems.