Fluid Coolers/Remote Condensers

Fluid Coolers and Remote Condensers

Our fluid coolers and remote condensers line of vertical and horizontal units have been designed to meet the special needs of the new installation market while having various options for the replacement market as well. Many unit installations should never utilize standard units because of the application or the environment. We have alternative materials for casings and frames with unlimited coil options to include corrosive resistant coatings. You can go with a cookie-cutter manufacturer or solve your problems with a system and application engineering group that will design a unit for your exacting requirements.

| UNIT TYPES |

|---|

| Horizontal & Vertical Series |

| Inline and Double Fan Configurations |

| 1 to 14 Fan Sizes |

| Direct Drive |

| Galvanized Steel Construction (G90 Frame and Cabinet) |

| APPLICATIONS |

|---|

| Supermarkets |

| Commercial Refrigeration Warehouse / Distribution |

| Power Plants |

| Air Conditioning Systems |

Shipping Option

Cost

4-5 weeks

Standard Shipment

1-2 weeks

(availability limited, based on design, size and materials)

Expedited Ship

See our Shipping Schedule for all other HVAC equipment offered.

Questions? Need more information?

Please call us at 800-USA-COIL!

Or send us a message using the form to the left.

Fluid Coolers and Remote Condensers Standard Features

* Custom Modular Design

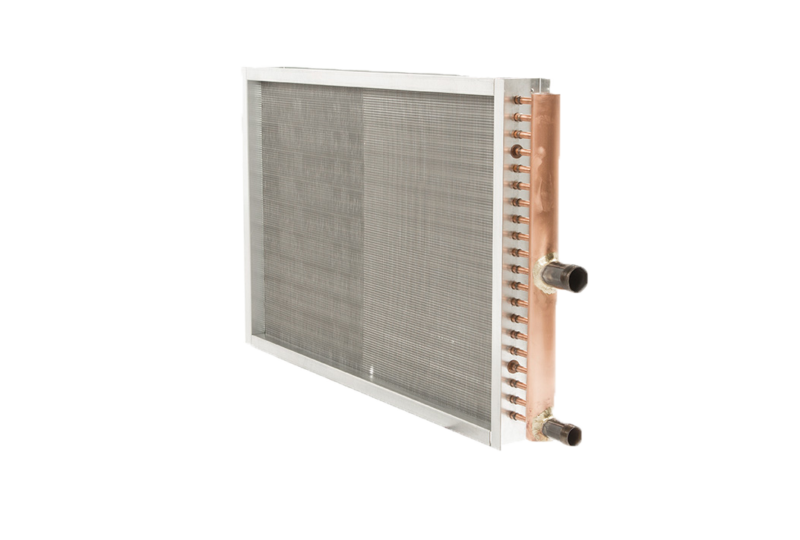

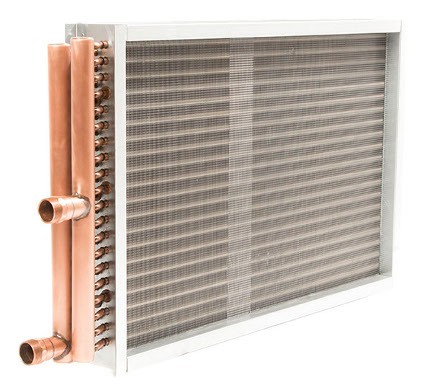

* 10 Fins per Inch Aluminum Fins with 3/8″ or 1/2″ OD Copper Tubes for Remote Condensers and 1/2″ or 5/8″ OD Copper Tubes for Fluid Coolers

* Two Section Manifolding for Dual Fan Width Units

* ETL Listed

* High-Efficiency Aluminum Fan Blades and Welded Steel Hubs

* TEAO VFD Compatible Low RPM Motors w/ 12 Gauge Motor Rails

* NEMA 3R Weatherproofing Enclosure with Easy Access

* Units Tested at 550 PSIG Remote Condensers tested w/ Nitrogen Charge and Shipped with Nitrogen Holding Charge

OPTIONAL FEATURES

(some features apply to remote condensers only)

| Variable fin per inch selection aimed at cleanability and higher efficiency | Building control interface |

| Numerous multi-circuit and sub-cooling capability | Control terminal blocks |

| Head pressure or ambient temperature fan cycling controls | Heavy duty tube and fin construction |

| Individual or paired motor fusing | Baked on corrosion resistant coatings |

| VFD controls or refrigerant rack controls | Polyester coated fin stock |

| Fused/ non-fused disconnect switch | Aluminum or stainless steel cabinet and frame |

| 24V or 120V Control circuits | Extended height legs for better ground clearance |

Latest From The Blog

View our latest blog news

-

What is Heat Transfer?

There are many terms used in the HVAC Industry. One that is often misunderstood is heat transfer. Wikipedia’s definition states that......

-

Invaluable Freeze Event Protection

USA Coil & Air has been marketing our patented, freeze-damage water and steam coil line for over 25 years under the......

-

It’s Coil Replacement Season

The “holiday season” may be over, but the “coil replacement season” is in full swing in many areas of the country.......