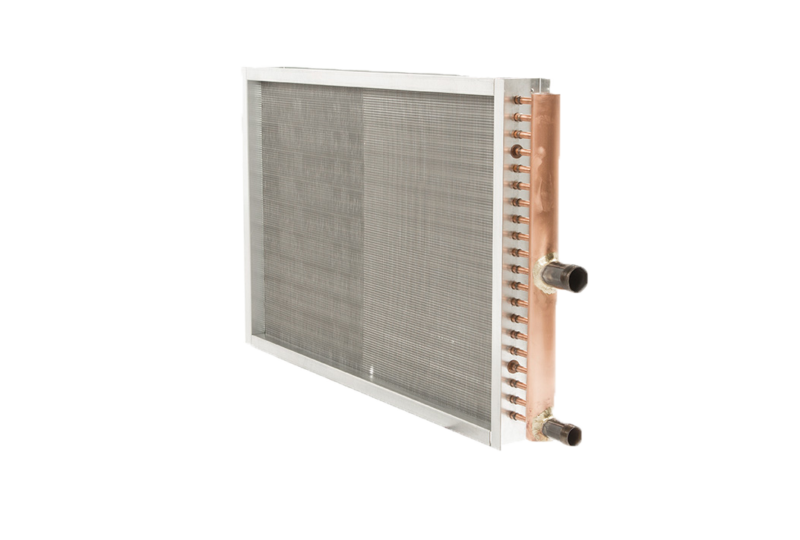

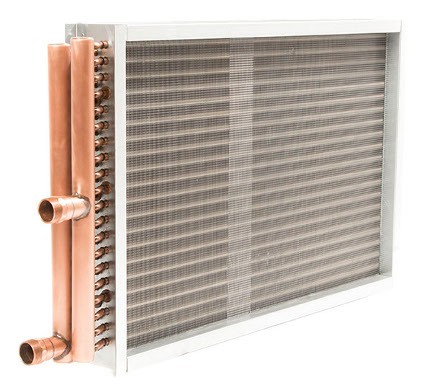

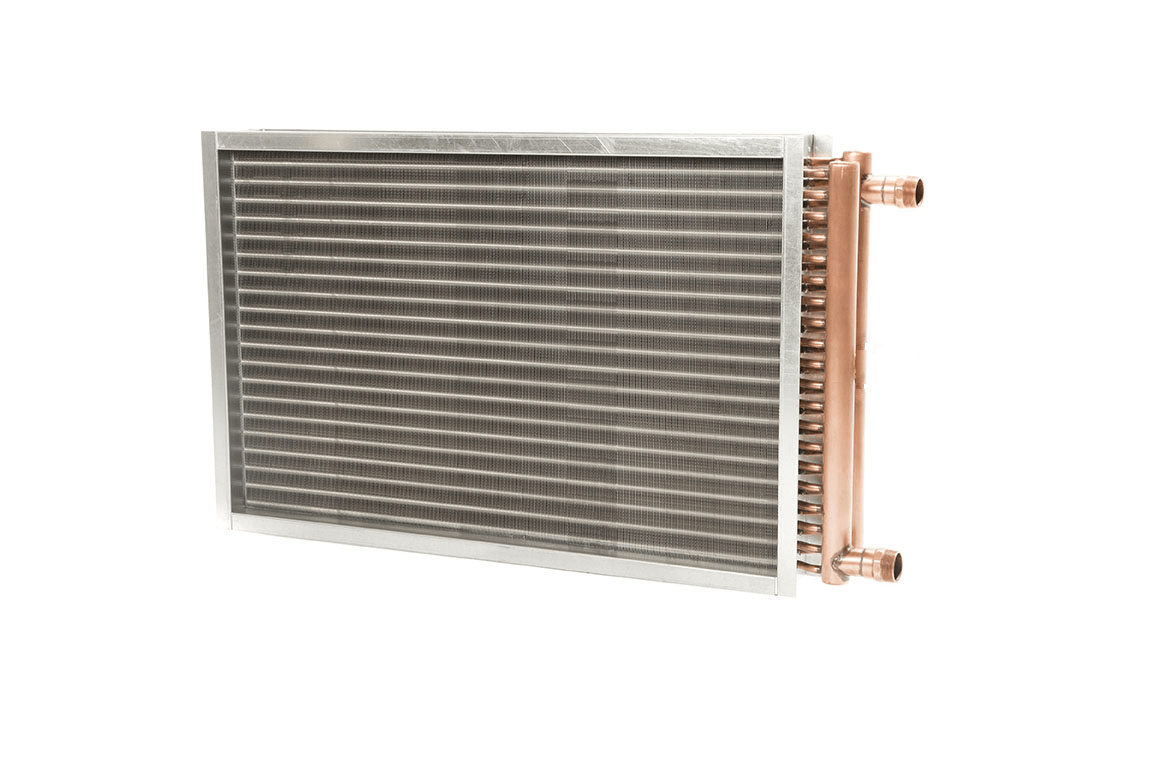

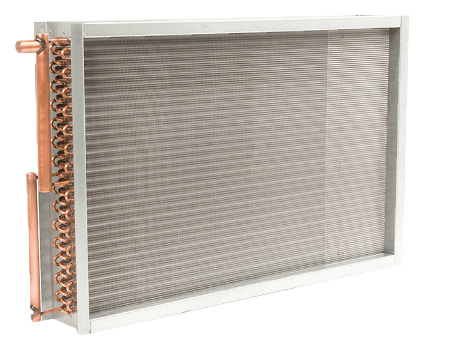

What is Heat Transfer?

There are many terms used in the HVAC Industry. One that is often misunderstood is heat transfer. Wikipedia’s definition states that heat transfer is a thermal engineering discipline that concerns the generation, use, conversion, and exchange of thermal energy between physical systems. It affects the measurement of heat. The various heat transfer types are thermal conduction, thermal convection, thermal radiation, and the transfer of energy...

Read More