FinKote2 Coil Coating

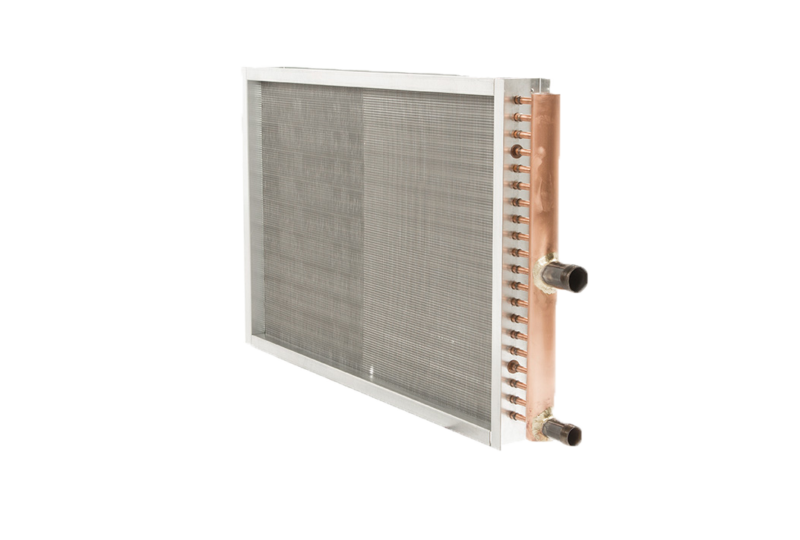

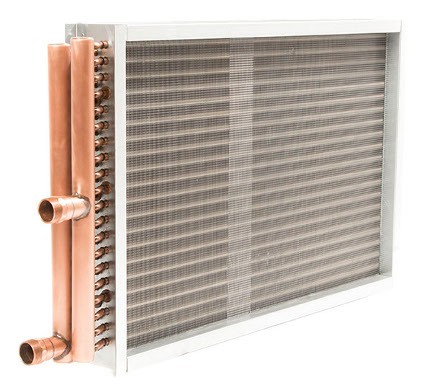

FinKote2 is the premium coating system for the HVAC industry. Years of ineffectual coatings in the HVAC market prompted the development of FinKote2 as a way of addressing the shortcomings. FinKote2’s high edge build e-coat effectively bonds to microchannel and tube and fin coils in AC units. Aluminum, copper, and steel coils are protected from corrosion, particularly coastal installations, and offshore projects, or anywhere environmental corrosion will cause premature failure of the coil. FinKote2 is the most technically advanced process available in the HVAC industry today.

The FinKote2 coating has shown to be the best option on the market for schools, hospitals, processing plants, airports, and many other commercial applications. Its chemical bond and durability make it compatible with all kinds of surfaces, materials, and manufacturing processes.

How It Works

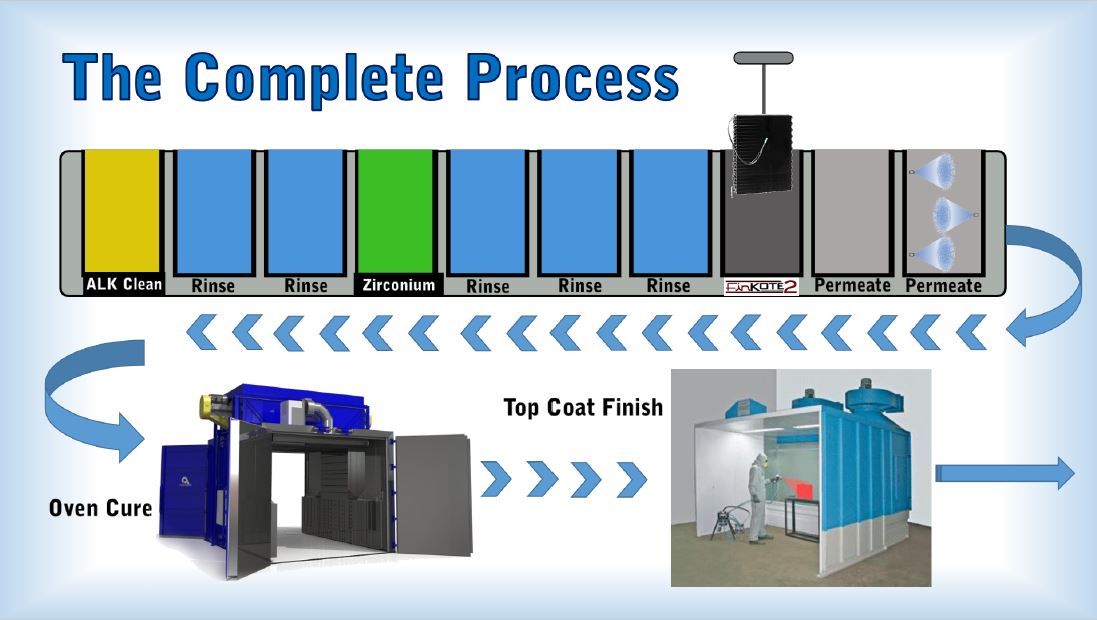

To start the process, a weak oxide layer that has formed on the bare aluminum surface needs to be removed. Heated alkaline cleaning is utilized to remove the oxide film and residual process lubricants. After cleaning, a neutral ph rinse is needed to stabilize the surface. An immersion application process deposits the zirconium oxide layer onto the coil surface. A conversion layer forms (nano-film build) on the surface providing improved fin edge build and adhesion. Zirconium corrosion resistance has been tested as a stand-alone material, showing improved protection. Over time, when a fin becomes exposed to the atmosphere, (micro-cracking from thermal movement, abrasion from airborne contaminants) the bond strength of the coating will be greatly diminished without a pretreatment, allowing for creep-back to occur.

After pretreatment, coils pass-through multiple rinse tanks to ensure a neutral ph surface. With our patented ZNET technology, film build is controlled to +- .0002. Anode control ensures no bridging and 100% coated to the center. Post rinse before curing ensures no loose material is left on the surface, contributing to an even film build. The final stage is an oven cure. Axalta E-coat material is a lower temperature cure (355F) than other E-coats on the market.

Ecoat 3 – 10 stage Manual Hoist Transfer System

Pretreatment

Recovery

Electro-Coat

Cure

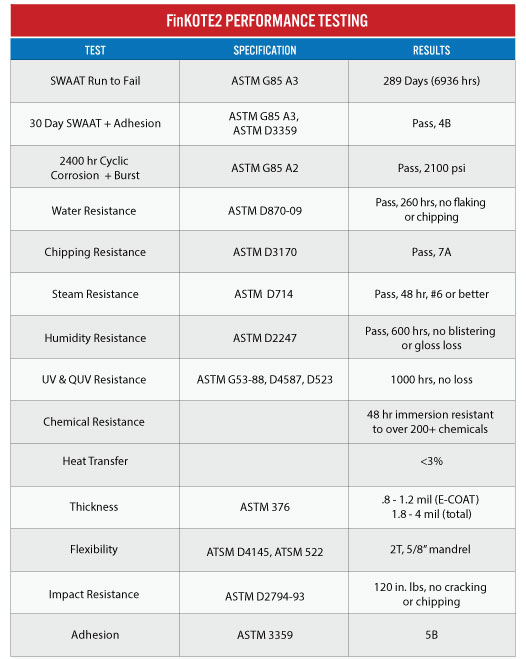

Performance Testing

Latest From The Blog

View our latest blog news

-

What is Heat Transfer?

There are many terms used in the HVAC Industry. One that is often misunderstood is heat transfer. Wikipedia’s definition states that......

-

Invaluable Freeze Event Protection

USA Coil & Air has been marketing our patented, freeze-damage water and steam coil line for over 25 years under the......

-

It’s Coil Replacement Season

The “holiday season” may be over, but the “coil replacement season” is in full swing in many areas of the country.......